With Tommy McNabb’s blessings I am pleased to continue the legacy of McNabb Presses at

GilmorePresses.com

Tommy passed on September 23, 2019.

"I met Tommy while teaching Pattern Development in Damascus Steel at the John C. Campbell Folk School in 1983. He was an outstanding student and we became fast friends. Tommy and I traveled from coast to coast as he photographed my architectural metalwork. We both enjoyed collaborating on projects from his shop in North Carolina to mine in Montana. I’m proud to have started building hydraulic presses with Tommy in 2006. Tommy’s great friendship is something I continue to cherish."" - Glenn Gilmore

Contact: 406-961-1861 or glenn@gilmoremetal.com

|

About the McNabb |

|

|

|

|

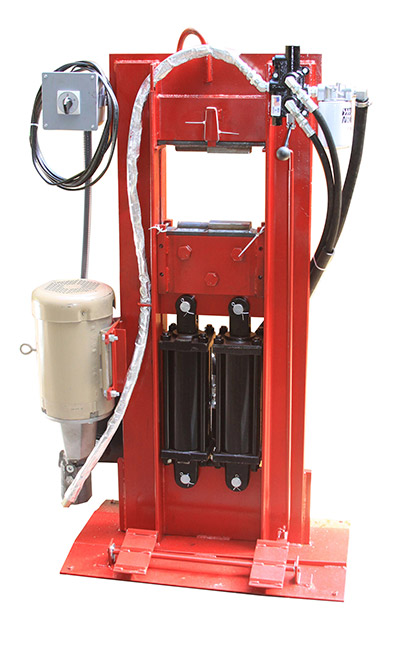

50 Ton Large Hydraulic Forging Press

50 Ton Capacity with an 10" Stroke. Painted "safety red"; with a 7.5 Horse Power Motor, 220 volts - 50 AMPS - Weight is 1300 lbs. 56" tall - Base is 24" x 32" The dies are rapidly interchangeable. |

24 Ton Small Forging Hydraulic Press

Painted "safety red"; with a 3 Horse Power Motor, 220 volts - Weight is 800 lbs. 52" tall - Base is 24" x 32" The dies are rapidly interchangeable. |

|

|

|

|

For more information and prices :